Gochang, South Korea, September 3, 2025

News Summary

Korea Electric Power Corporation has introduced S-CAP, a data-driven software tool that standardizes submarine cable protection by quantifying risk, recommending optimized protection measures and producing design reports. S-CAP accepts site-specific inputs such as anchor types, wave and current conditions, and detailed seabed properties to calculate variable burial depths and recommend alternatives like rock berms or concrete ducts. Backed by numerical modelling and full-scale tests at a large Korean testing centre, the program has received formal document verification and has been applied to a major offshore wind grid link, delivering improved transparency, lower repair risk and cost savings.

New engineering software verified for submarine cable protection, deployed in Korea as major regional cable projects move ahead

A newly developed engineering program for designing submarine cable protection was formally verified in early 2024 and has already been used on a Korean offshore wind export link. The tool standardizes how projects measure marine risks, calculates optimized burial depths and proposes protection structures where burial is not feasible. The announcement comes as multiple large undersea cable projects move forward across East Asia and the Pacific, including a 260 km telecom link between Busan and Fukuoka and a 12,500 km subsea route connecting East Asia and California.

What the system does and why it matters

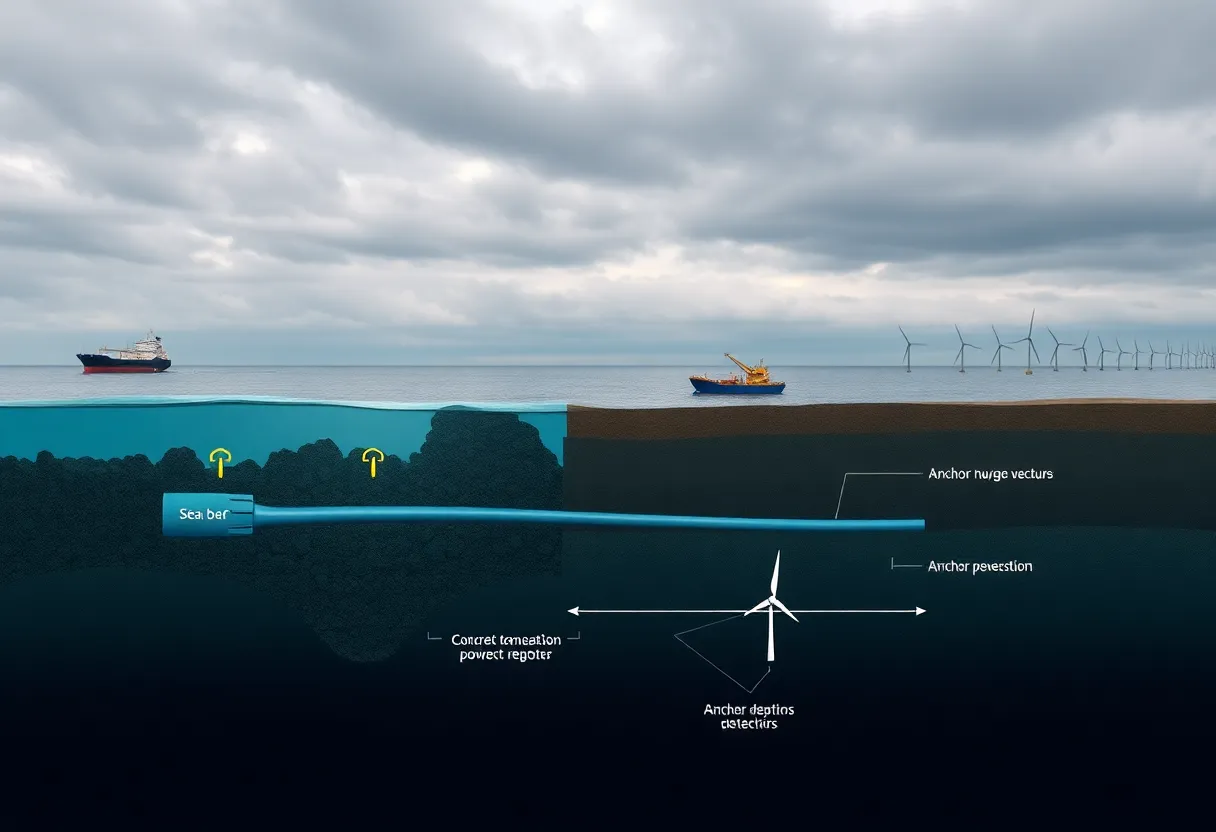

Submarine cables are central to modern electricity and data networks, linking offshore generation and interregional connections to population and data centers on land. Recent cable failures in other regions have shown that repair can be extremely costly and can threaten supply stability. The new software turns cable protection from a largely subjective engineering step into a data-driven design process. It accepts environmental and engineering inputs — such as anchor types and weights, wave height, current speed and seabed parameters like unit weight, undrained shear strength and internal friction angle — and then calculates recommended protection by route segment.

How it improves on legacy methods

Traditional approaches often use uniform minimum burial depths or rules of thumb that do not reflect local seabed layering or site-specific anchor risks. In soft seabed, trenching and burial are commonly used. In hard rock or deep water where burial is impractical, options such as rock berms and concrete ducts are applied. However, standardized global design criteria for these alternatives are limited, leaving many projects to rely on outdated practices that can either over‑protect and raise costs or under‑protect and risk damage.

Data-driven features and outputs

- The program calculates variable burial depths tailored to local marine risk rather than a flat depth everywhere.

- It proposes multiple protection options, including quantified specifications for rock berms and other protective structures — covering dimensions, materials and installation tolerances.

- It produces cross‑sectional drawings and a comprehensive design report aimed at improving documentation and traceability.

- The design approach converts a core empirical finding — that burial depth must exceed the sum of maximum anchor penetration plus a safety margin — into formula‑based charts and standards for practical use.

Testing, validation and claimed savings

The software’s methods were supported by extensive numerical simulations and full‑scale validation tests at a large power testing site in Korea spanning nearly 741,000 square metres. Those trials informed the engineering standard that links anchor penetration and safety margins to burial depth. A global certification body issued a formal document verification in February 2024, marking a first for a submarine cable protection method in terms of scientific rigor and quantitative procedures.

On paper, the approach is presented as both safer and more economical: estimated construction cost reductions of around 5% or roughly USD 2 million per 100 km are cited, and a specific offshore wind‑to‑land connection in Korea reported larger local savings when the software was applied — a claimed installation cost reduction near 50% for that project, equating to about USD 3.6 million — along with reduced environmental impact and clearer reporting between owner and contractor.

Where it has been used and where it could be applied

The program has been used on a Southwestern Offshore Wind‑to‑Land Connection project in Korea with grid connection targets in the late 2020s. It is suitable for both HVDC and AC submarine cable systems and is intended for use across offshore wind arrays, high‑voltage transmission corridors and interregional interconnections. By offering traceable, quantified design logic, the software aims to reduce disputes and improve constructability.

Major submarine projects running in parallel

Several large subsea cable projects are progressing in the same region. A consortium has secured a turnkey contract to build a roughly 260 km undersea telecom link between Busan and Fukuoka, due for completion by 2027; this project is aimed at increasing connectivity and carrying rising data loads from cloud and AI services. Separately, construction has begun on a long‑haul subsea cable connecting East Asia and the United States. That cable will extend about 12,500 km, land in Taiwan, South Korea, Japan and California, carry more than 192 Tbps across 12 fiber pairs, employ 18 kV powering technology, and is scheduled to enter service in the second half of 2028.

Risk reduction and broader benefits

Reliable protection lowers the chances of outages and expensive repairs, preserves service for island and remote communities, and helps ensure uninterrupted power and data flows in an era of rapidly rising demand for electricity and connectivity. A standardized, quantified design tool can also reduce subjectivity, improve tender clarity and help balance safety with cost efficiency by applying protection only where required.

Technical and operational limits to keep in mind

- In complex seabed profiles with multiple layers, simple indexes that assume uniform seabed properties can be misleading.

- Where physical burial is impossible, engineered protective structures must be sized, placed and specified to local standards and tolerances.

- Designs remain sensitive to accurate input data: anchor characteristics, seabed strength parameters and dynamic water conditions are all critical.

FAQ

What is the purpose of the new submarine cable protection software?

The software provides a quantified, data‑driven method to calculate burial depths and recommend protective structures for submarine cables based on local marine and engineering inputs.

How does it differ from traditional methods?

Unlike legacy approaches that often use uniform burial depths or empirical rules, the program applies variable burial depths and quantified standards for protective structures depending on site‑specific risks.

What inputs are required?

Key inputs include anchor types and weights, wave height, current velocity and seabed properties such as unit weight, undrained shear strength and internal friction angle.

Has the method been tested and verified?

Yes. The approach was validated with numerical simulation and full‑scale tests at a large testing site, and a global classification body issued a document verification in February 2024.

What projects have used the software?

The tool was used on a Southwestern Offshore Wind‑to‑Land Connection project in Korea. It is positioned for broader use on offshore wind, HVDC and AC submarine cable projects.

What savings are claimed?

Reported potential savings include approximately 5% in construction cost (around USD 2 million per 100 km) and larger local savings reported on a specific Korean offshore link.

Key features at a glance

| Feature | Details |

|---|---|

| Primary function | Quantified design of submarine cable protection and optimized burial depth per route segment |

| Inputs | Anchor types/weights, wave height, current velocity, seabed unit weight, undrained shear strength, internal friction angle |

| Outputs | Recommended burial depths, protection options, cross‑section drawings and design reports |

| Validation | Numerical simulation and full‑scale tests at a 741,000 m² testing site; document verification issued Feb 2024 |

| Project examples | Southwestern Offshore Wind‑to‑Land Connection (Korea); regional telecom link Busan–Fukuoka; long‑haul E2A subsea cable |

| Claimed benefits | Improved design accuracy, reduced subjectivity, potential cost savings and lower environmental impact |

| Applicability | HVDC and AC submarine cables, offshore wind export, interregional transmission |

Deeper Dive: News & Info About This Topic

Additional Resources

- Korea JoongAng Daily: LS Cable wins $115M submarine cable order from Taiwan

- Wikipedia: LS Cable & System

- Capacity Media: LS Cable joins Korea–Japan submarine cable project

- Google Search: Korea Japan submarine cable Busan Fukuoka

- Financial Times: Subsea cable / industry coverage

- Google Scholar: submarine cable protection anchor penetration

- DataCenter Dynamics: Construction begins on E2A subsea cable connecting US to Asia

- Encyclopedia Britannica: E2A subsea cable

- Inspenet: Taihan secures subsea cable contract for Korea offshore wind project

- Google News: Taihan subsea cable Korea offshore wind

Author: Construction NY News

The NEW YORK STAFF WRITER represents the experienced team at constructionnynews.com, your go-to source for actionable local news and information in New York and beyond. Specializing in "news you can use," we cover essential topics like product reviews for personal and business needs, local business directories, politics, real estate trends, neighborhood insights, and state news affecting the area—with deep expertise drawn from years of dedicated reporting and strong community input, including local press releases and business updates. We deliver top reporting on high-value events such as the New York Build Expo, infrastructure breakthroughs, and cutting-edge construction technology showcases. Our coverage extends to key organizations like the Associated General Contractors of New York State and the Building Trades Employers' Association, plus leading businesses in construction and real estate that power the local economy such as Turner Construction Company and CMiC Global. As part of the broader network, including constructioncanews.com, constructiontxnews.com, and constructionflnews.com, we provide comprehensive, credible insights into the dynamic construction landscape across multiple states.